Small Batch Technology Example

Why small batches are better than large idea of the day 132 duration. By producing in large batch sizes the small business can reduce their variable costs and obtain bulk discounts from material suppliers.

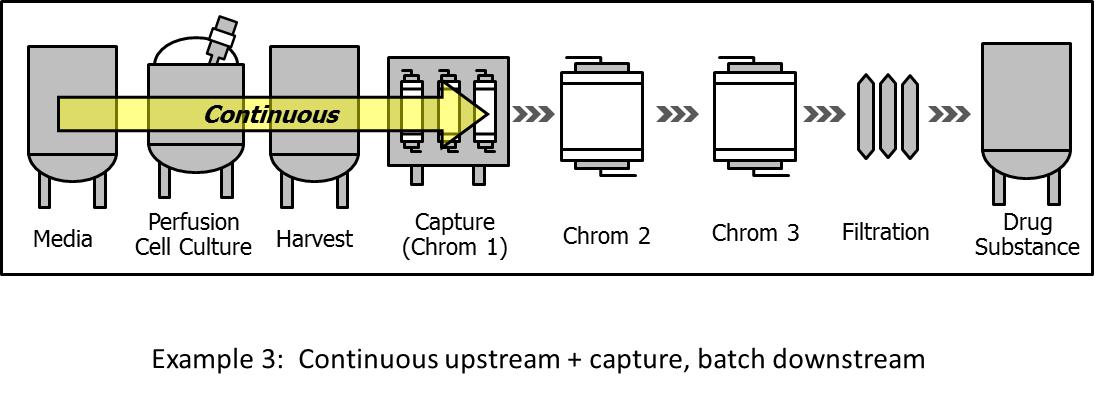

White Paper 4 International Symposium On Continuous

Cmt cut make and trim this is another way to say cut and sew manufacturing.

Small batch technology example. Some examples of batch production include the manufacture of cakes and shoes newspaper publishing cloth production the publication of books and the manufacture of pharmaceutical products. First line supervisors have narrow span of control in small batch technology wide in mass production technology and small in continuous process technology. Is small batch manufacturing a viable option in the united states.

This makes efficient use of equipment and is common in industries such as bakeries and packaged food goods. Batch production has several advantages including the fact that it does not require skilled workers and takes a short period of time. With the large batch approach we wouldnt find that out until nearly the end.

Idea of the day 862 views. 93 small batch technology needs a flat three leveled hierarchy with decentralized decision making and a narrow span of control for supervisors 23 employees. This includes the entire assembly of the garment.

For example imagine that the letters didnt fit in the envelopes. Small batch manufacturers typically start at 50 100 units per style but there are a few factories that offer zero minimums like us. This represents a paradigm shift in strategy for manufacturing small batch cell based products.

Many small businesses i work with try to manufacture their product in as large of batch sizes as are possible. For example the same production equipment may be used to produce both cookies and bagels. The production equipment may be cleaned and reconfigured between batches.

Large batch manufacturers set their minimums around 500 1000 units per style. If the amount of time that each process took was exactly the same the small batch production approach still would be superior and for even more counterintuitive reasons. Best of all these 10 small batch factories are proudly made in america.

The reasoning behind this is the potential for economies of scale. Efficient small batch processing also provides an option to scale out with multiple identical small scale systems rather than scaling up batch sizes. The answer is yes.

One important theme in this chapter is how core technology influences organization structure. Weve hunted down 10 small batch factories doing big things for small business emerging designers and even some very large brands looking to create limited edition products. What is small batch technology and provide example manufacturing and service technologies technology refers to the work processes techniques machines and actions used to transform organizational inputs into outputs.

Batch production lends itself well to situations where batches are unique.

Batch Vs Real Time Data Processing Data Science Central

Individual Solutions Schnorr Gmbh

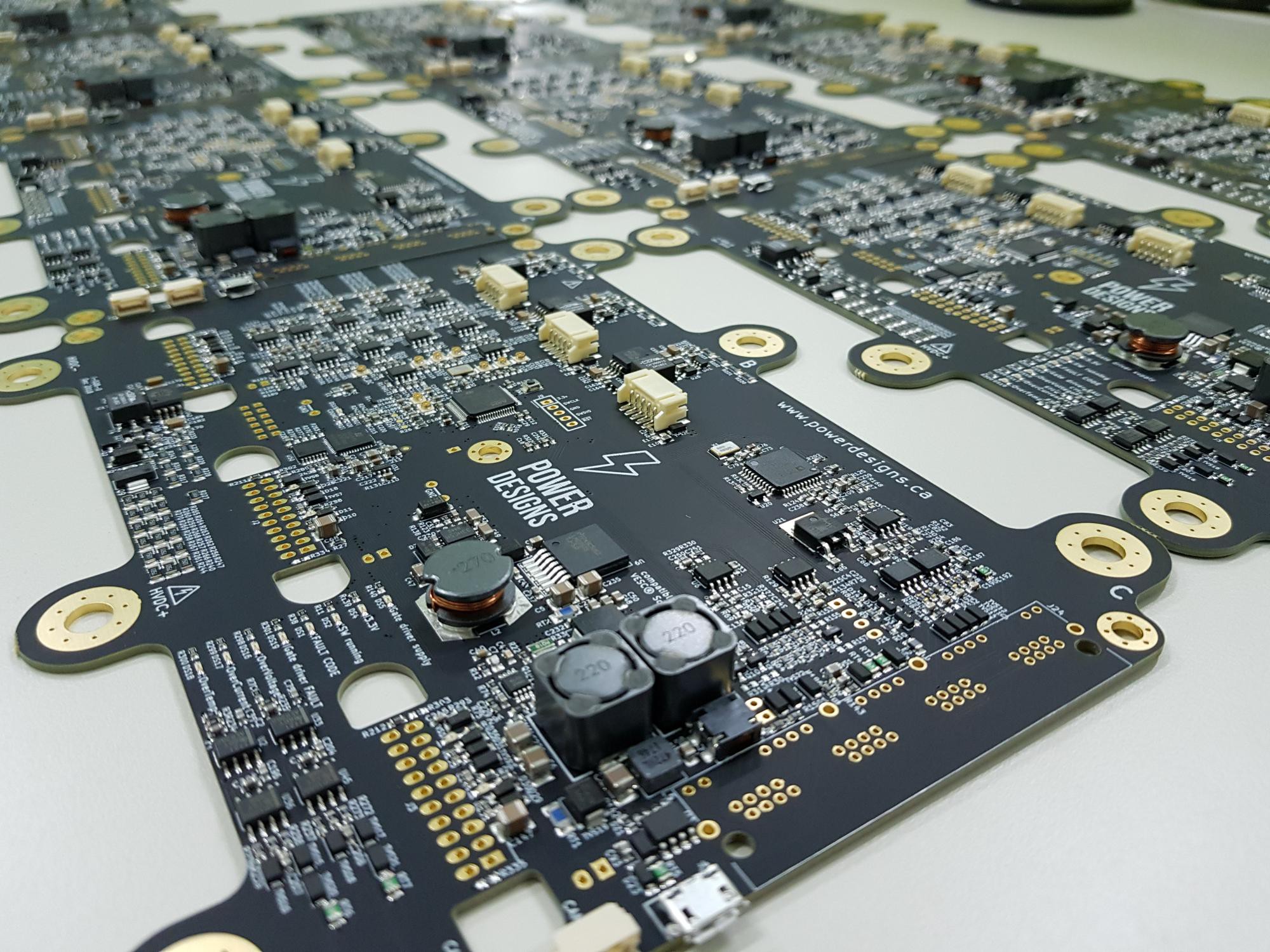

Design For Manufacture Board Level Details Hackaday Io

Advances And Challenges In Vaccine Development And Manufacture

Production Planning For Small Manufacturers Mrpeasy

Ml Mini Batch K Means Clustering Algorithm Geeksforgeeks

The Future Of Manufacturing Technology L Cb Insights

Ml Mini Batch K Means Clustering Algorithm Geeksforgeeks

Big Data Battle Batch Processing Vs Stream Processing